INDUSTRIAL ROBOTS PERFORM DANGEROUS AND HEAVY BATTERY DISASSEMBLY USING AI

PAVING THE WAY FOR SAFER RECYCLING

LAUSANNE, SWITZERLAND – October 7, 2025

Disassembling high-voltage Electric Vehicle (EV) batteries is a dangerous, manual process that creates a bottleneck for the circular economy. To solve this challenge, the Eureka-funded Project LAMBDA brought together three partners—AICA, Circu Li-ion, and the Swiss Battery Technology Center (SBTC)—to teach an industrial robot how to perform this complex task with a human-like sense of touch.

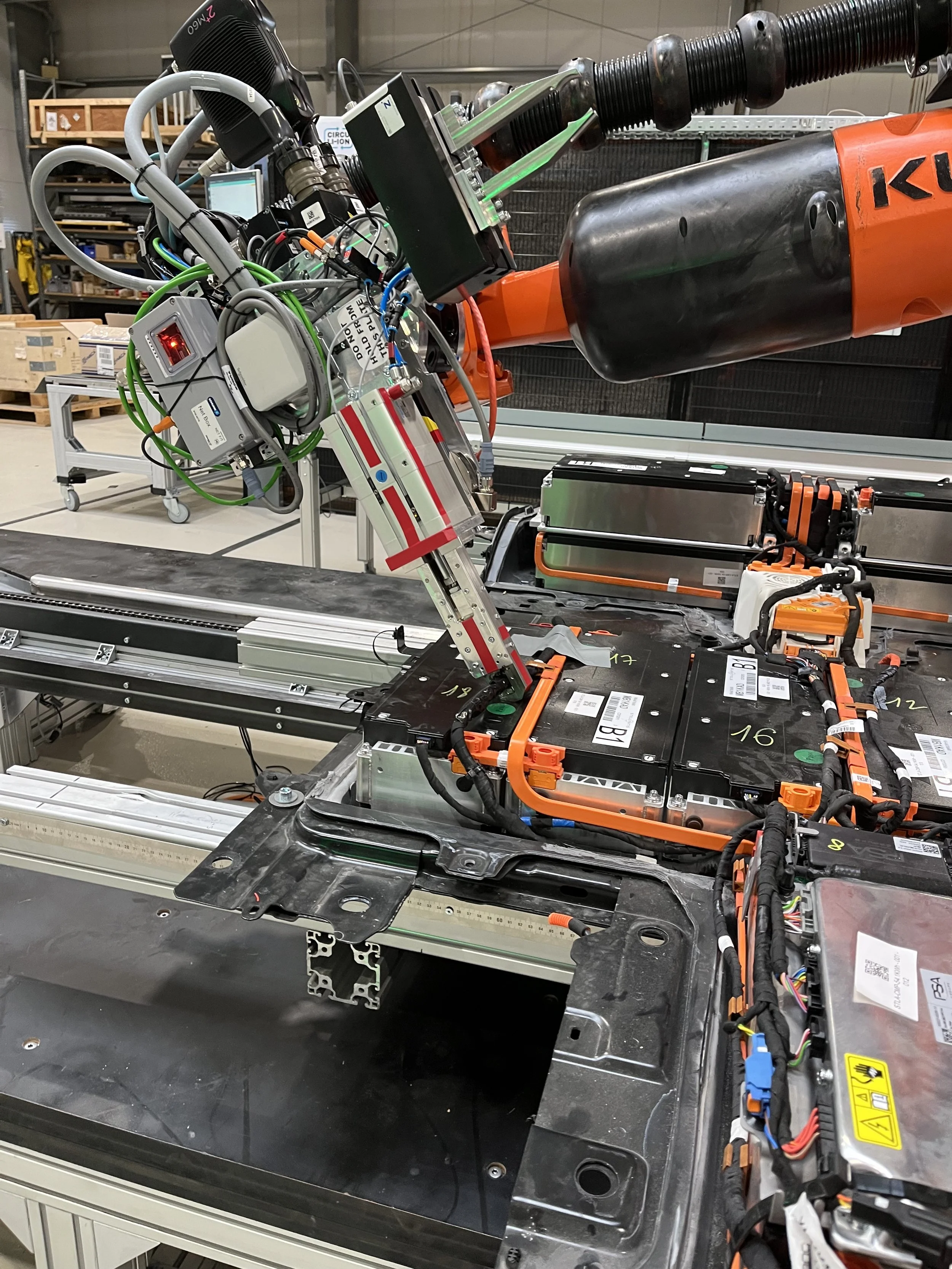

The project’s final testing concluded at Circu Li-ion's battery disassembly line in Luxembourg. There, the team successfully deployed their software on an industrial Kuka robot, demonstrating a pioneering application of an AI-based tactile control policy in a production environment. The system used 3D vision and force feedback on a neural network trained in simulation with Reinforcement Learning (RL) to drive the robot, culminating in the successful cutting and removal of a cable harness on a real, high-voltage EV battery pack. This achievement represents a significant step in taking human operators out of harm's way and bringing learning-based manipulation to industrial applications.

This successful demonstration was the result of a deeply integrated partnership. The SBTC contributed the foundational research on robot learning and sim-to-real methods. They developed simulated environments and low-level control strategies for dexterous robotic skill training, and optimized RL workflows for training and deployment, reducing the sim-to-real gap in a controlled lab environment. The findings from their work were used to identify the best opportunities for using RL in industrial settings.

This successful demonstration was the result of a deeply integrated partnership. The SBTC contributed the foundational research on robot learning and sim-to-real methods. They developed simulated environments and low-level control strategies for dexterous robotic skill training, and optimized RL workflows for training and deployment, reducing the sim-to-real gap in a controlled lab environment. The findings from their work were used to identify the best opportunities for using RL in industrial settings.

“Our mission at the SBTC is to de-risk and accelerate the adoption of new technologies for the battery industry,” explained Christian Ochsenbein, Head of SBTC. “By first conducting the foundational research and then validating the AI approach in our specialized labs, we built the confidence needed for our partners to deploy it in a live industrial setting."

As consortium lead and software integrator, AICA was responsible for bridging the gaps between research and industry with project management and the core adaptive control technology. Their pipeline used real-world robot data to improve the realism of simulated environments and could seamlessly deploy trained RL policies for real-time execution. This technology enabled the robot to learn and master complex skills in a virtual environment before applying them to the physical task.

When it comes to adaptive and force-sensitive control, the gap between simulation and reality is still huge,” said Enrico Eberhard, Co-founder and CTO of AICA. “With the LAMBDA project, we've demonstrated a powerful and practical way to tackle that gap on real industrial robots, not just on fine-tuned research platforms. Our pipeline makes retraining and deploying new behaviors from simulation efficient and practical, marking a major step forward for more intelligent and flexible automation."

For the final validation, Circu Li-ion provided the industrial expertise and environment. Their team engineered the physical workstation, created the integrated tooling, and developed the complete Battery Disassembly Line. In addition to providing access to real EV batteries, they led the final product validation, defining the specific skills and processes for the robot to perform.

"At Circu Li-ion, we've already automated significant parts of the battery disassembly process, but certain delicate, high-risk tasks have remained a challenge for traditional robotics," said Xavier Kohll, CTO at Circu Li-ion. "This project proves that reinforcement learning can solve these complex steps. Integrating this advanced AI into our line allows us to tackle the final frontiers of automation, pushing the boundaries of what's possible in safe and scalable battery recycling."

This demonstration from Project LAMBDA marks a critical milestone, showcasing the potential of learning-based robotics to solve real-world industrial challenges and paving the way for further development in demanding environments.

AICA is a Swiss robotics software company spun out of EPFL’s LASA lab, dedicated to transforming industrial automation. Its technology bridges AI-driven software and real-time sensor control with industrial hardware, making robotic systems easier to program and deploy. Backed by over CHF 3.5 million from investors including Momenta, Spicehaus Partners, Hightech Gründerfonds, Schaeffler Invest, and Innosuisse, AICA is driving the adoption of intelligent, flexible automation across industries.

About AICA:

The SBTC is one of four research centers of the Switzerland Innovation Park Biel/Bienne (SIPBB). The Switzerland Innovation Park Biel/Bienne is a private Swiss non-profit organization that conducts and supports industry-oriented and primarily applied research and development.

The SBTC conducts research in the areas of battery ageing, battery applications, and battery disassembly. At the SIPBB, a research laboratory for automatic battery disassembly and recycling of lithium-ion batteries is being built, which is unique in Switzerland.

About SBTC:

About Circu Li-ion:

Circu Li-ion is a Luxembourg-based startup pioneering safe, efficient, and automated disassembly for end-of-life products, with EV batteries and e-motors as our first focus area. Our technology combines robotics, vision systems, and AI-driven workflows to dismantle batteries to module and component levels. By recovering functional parts and critical raw materials, we enable repair, reuse, and recycling pathways that extend product life and reduce environmental impact.

Trusted by industry leaders and innovators across Europe, Circu Li-ion helps partners comply with the EU Battery Regulation, raise safety standards, and boost circularity. With flexible pilot programs and scalable solutions, we are redefining how industries handle end-of-life products — transforming challenges into opportunities for profitability and sustainability.

Eurostars: Support for research in SMEs:

Eurostars is aimed at innovative small and medium-sized enterprises, i.e. those that develop processes or products that differ significantly from their previous activity. Thanks to Eurostars, SMEs can collaborate with the research teams of the most appropriate partner countries of the program and strengthen their competitiveness in the field of know-how and innovation. All thematic areas are eligible. Calls for innovative projects are regularly published on the Eureka website.

The LAMBDA project is also supported by:

In Switzerland: Innosuisse – Swiss Innovation Agency

In Luxembourg: Luxinnovation & Ministry of Economy

Media Contact

Olha Kulchytska - Marketing Specialist - press@aica.tech